Metallurgical Intelligence® licensing

Choose the option that’s right for your operation

Fast-track your digital transformation with the world’s only enterprise-wide digital twin for mining processing plants, now available in three licensing options

Advanced functionality, customisation and capabilities are the same regardless of the model you choose

- A digital twin solution, fully customised to your operation

- Migration of any existing data

- Integration with existing solutions/applications

- Configuration and installation

- In-depth training, customised to your requirements

- Ongoing support from Metallurgical Systems

AT A GLANCE

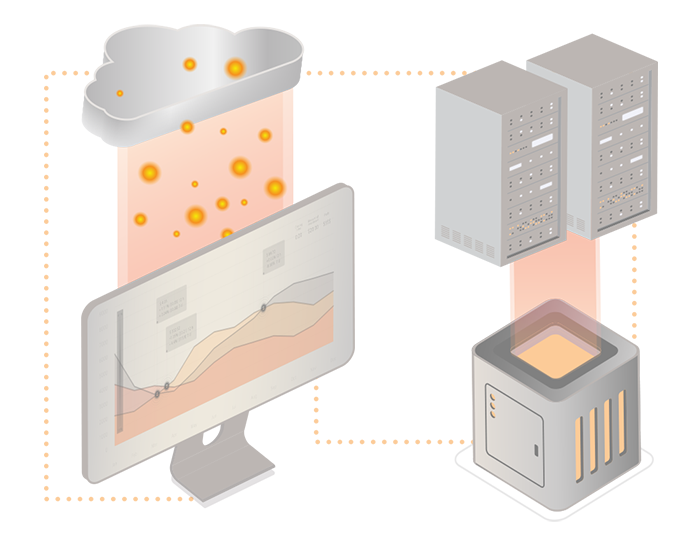

Step 1: Choose the licensing and delivery option that’s best for you

| Traditional (capex) licencing unlimited users, all features |

Subscription (opex) licencing unlimited users, all features |

Subscription (opex) licencing unlimited users, all features |

| Applications (Managed by customer) | Applications (Co-managed) | Applications (Managed by Metallurgical Systems) |

| Data (Managed by customer) | Data (Co-managed) | Data (Managed by Metallurgical Systems) |

| IT Infrastructure (Managed by customer) | IT Infrastructure (Co-managed) | IT Infrastructure (Managed by Metallurgical Systems) |

Step 2: Choose the level of support you need

|

|

|

THE DETAIL

Compare Metallurgical Intelligence® licensing models

On Premises

Your on-premises servers.

Best for:

|

Benefits:

|

Responsibilities:

|

Pricing model:

|

Access:

|

Support:

|

Hybrid

A public or private cloud, maintained and managed by Metallurgical Systems.

Best for:

|

Benefits:

|

Responsibilities:

|

Pricing model:

|

Access:

|

Support:

|

Software-as-a-Service (SaaS)

A public or private cloud, maintained and managed by Metallurgical Systems.

Best for:

|

Benefits:

|

Responsibilities:

|

Pricing model:

|

Access:

|

Support:

|